CONWAY, Ark. – March 10, 2025 – BMW® has approved the use of two innovative Car-O-Liner® products, the CTR™9 fully automatic resistance spot welder and the CDR™1 cosmetic dent repair workstation, for service and repair procedures performed on BMW vehicles worldwide.

The CTR9 fully automatic welder features a revolutionary lightweight transformer gun with a 355° swivel handle and an ergonomic grip design, allowing users to maintain optimal working positions for any task. The gun is supported by a telescopic arm made of durable, lightweight extruded aluminum, which can be easily adjusted both vertically and horizontally.

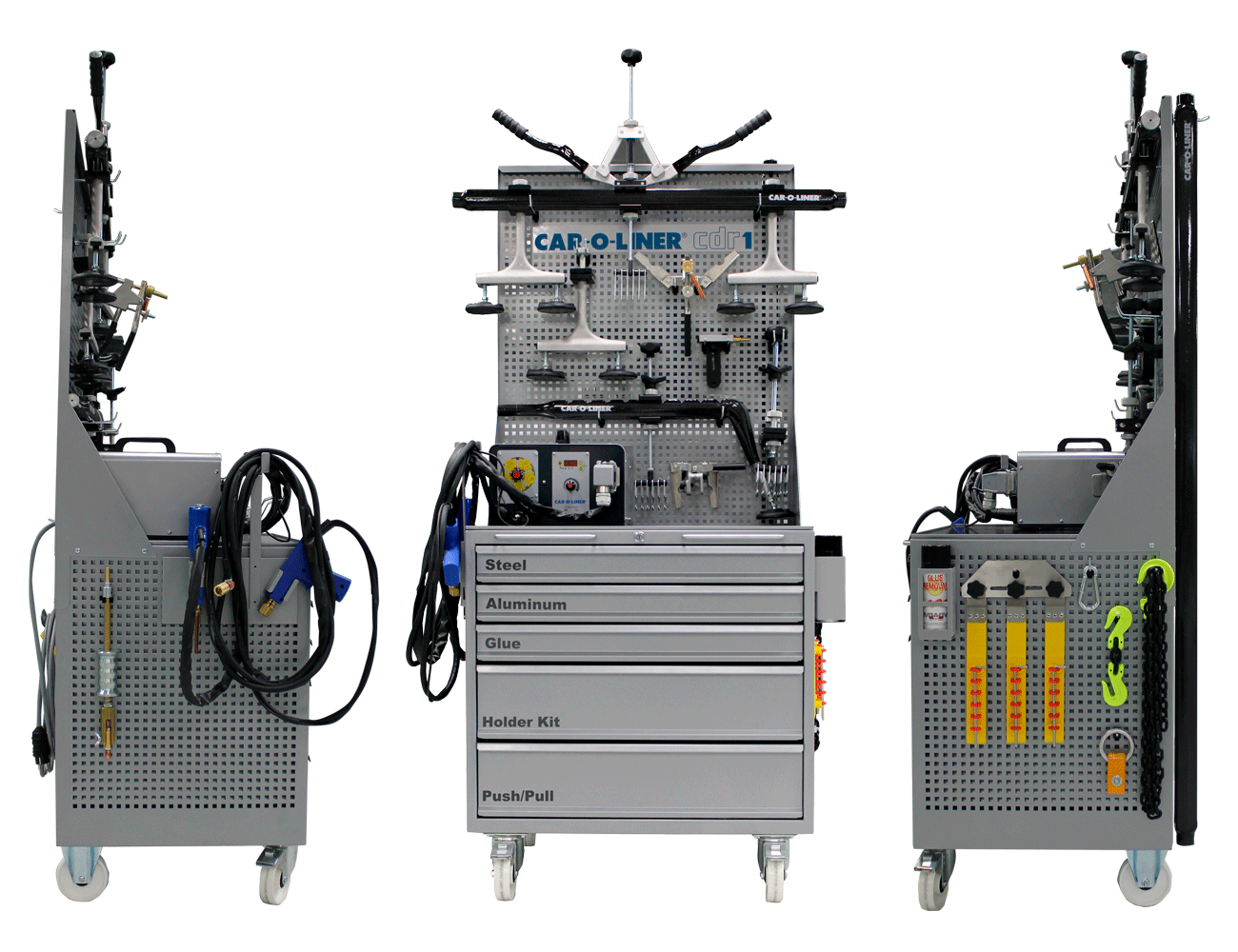

Designed as an all-in-one solution for light cosmetic dent repair, the CDR1 is a versatile, value-packed repair cart that enables technicians to efficiently perform professional repairs on small to medium autobody damage.

“We are honored that the industry-leading Car-O-Liner CTR9 and CDR1 have been approved for use on BMW vehicles,” said Tim Garner, national accounts and OEM sales manager for Car-O-Liner. “This endorsement underscores the superior quality and performance of Car-O-Liner equipment, making them indispensable, productivity-enhancing solutions for professional workshops.”