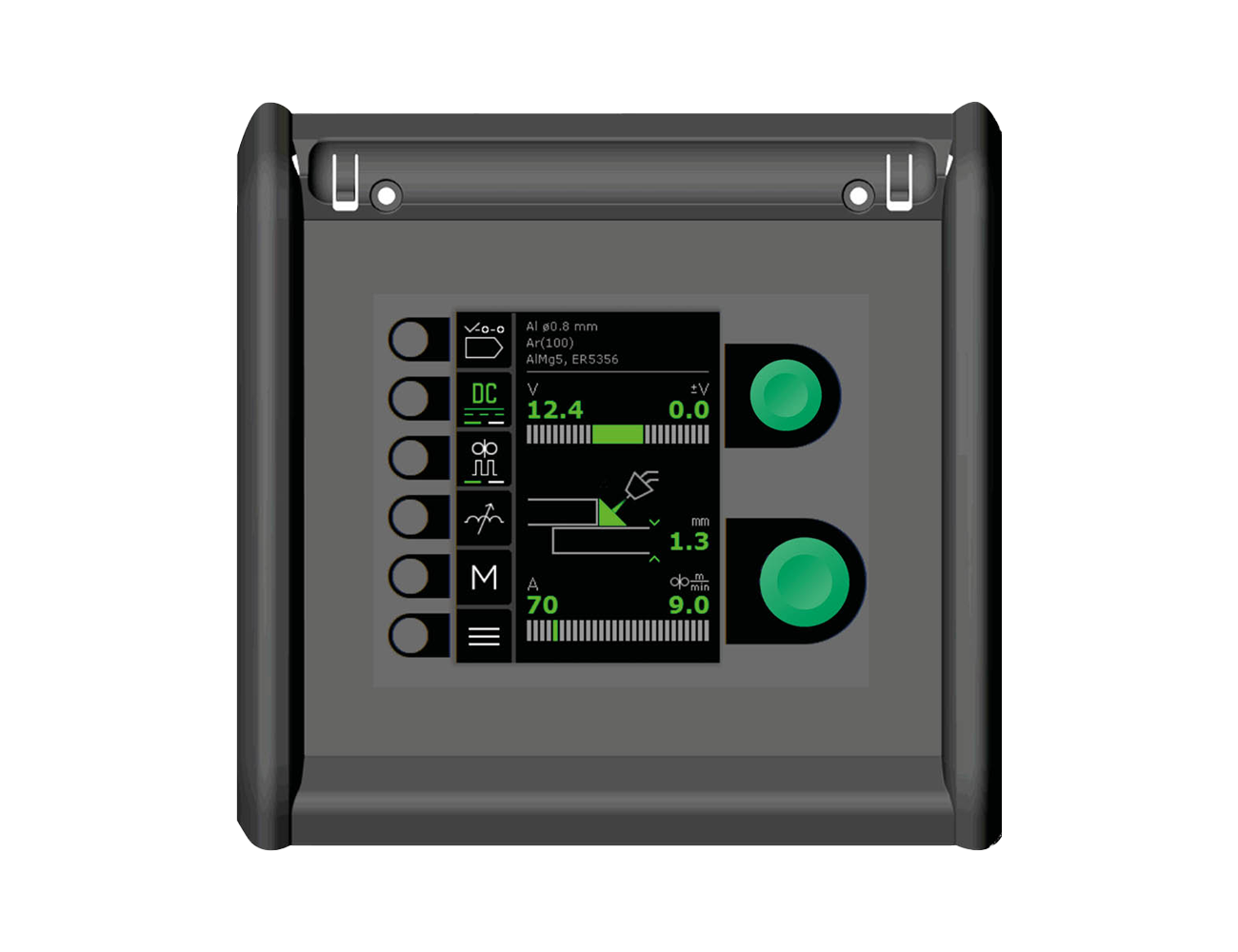

Pulse Welder Overview

A pulse welder like the CMI™ 300 is a welding machine that utilizes a pulse current to join metals. Unlike traditional methods that use a constant welding current, pulse welding alternates between high and low current levels. This pulsing action allows for more precise control over the heat input, minimizing distortion and providing a cleaner end result. The process is especially beneficial for working with thin materials or metals that are prone to warping. Pulse welders are commonly used in applications requiring high-quality welds with minimal spatter and improved aesthetic appearance.

The CMI™ 300 Pulse is also a joint MAG and MIG welder, offering the flexibility to work with both aluminum and steel materials. MIG welding, also known as Gas Metal Arc Welding (GMAW), uses a continuously fed wire electrode and a shielding gas to protect the weld pool from contamination. MAG welding, or Metal Active Gas welding, is a process that uses a continuously fed wire electrode and an active shielding gas, typically a mixture of argon and carbon dioxide, to weld metals, providing stable penetration and high productivity. With both shielded and active gas options, this machine offers the best all-around welding conditions for any shop.

Benefits of Using a Pulse Welder in Collision Repair

Precision and Control: Pulse welding equipment offers greater control over the heat input, which is critical in collision repair where precision is needed to avoid further damaging the vehicle. This precision ensures that the welds are strong and reliable without compromising the structural integrity of the repaired areas.

Reduced Heat Distortion: The pulsing action reduces the overall heat input, minimizing the risk of warping and distortion. This is particularly important when working with thin automotive panels and components that can easily deform under excessive heat.

Cleaner Welds: Pulse welders achieve cleaner results with less spatter compared to conventional methods, which also enhances the overall appearance of the repair.

Versatility: This method is versatile and can be used on a variety of metals commonly found in vehicles, including aluminum welding, stainless steel welding, and high-strength steel welding. This versatility makes pulse welders a valuable tool in the collision repair industry where different materials are frequently encountered.

Improved Efficiency: Pulse welders often allow faster welding speeds and higher deposition rates, increasing productivity. This efficiency is beneficial in a busy collision repair shop where time is of the essence.